The EcoZert certificate from Creditreform Hannover-Celle Bissel KG recognises companies that can demonstrate sustainable, ecological and socially responsible business practices. It confirms that INTECH fulfils certain sustainability criteria, for example in the areas of environmental management, resource consumption and social responsibility. This makes INTECH's commitment to sustainable corporate management visible.

You are welcome to take a look at our sustainability certificate:

EcoZert certificate (PDF document)

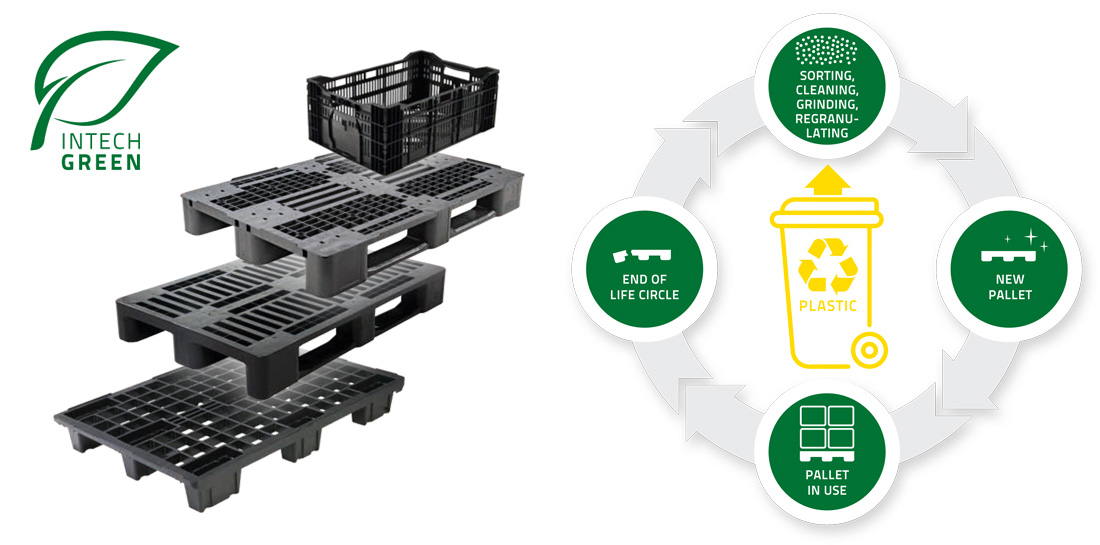

With our sustainability program "Intech Green," we commit to using high-quality recycled materials made of 100 % PCR plastics. Post-consumer recycled materials (PCR) are plastics re-processed from household or commercial waste, the majority of which come from packaging. INTECH processes over 10,000 tons of these materials each year, giving these valuable raw materials a new life. At the end of their service life, we take back containers and pallets, recycle their materials once again, and close the cycle. Our recycling rate is 100 % – fully in line with the concept of the circular economy.

Environmental awareness is growing, and climate change is accelerating this positive trend. This awareness is focused on reducing CO2 emissions.

A CO2 footprint or carbon footprint is a way to measure emissions of CO2 due to the consumption of fossil fuels in the areas of transportation, power generation, heat production, traffic, and consumption.

Contrary to common assumptions, plastic pallets achieve better results than their wooden counterparts from an ecological standpoint. The difference is even more clear if we compare our reusable containers with disposable packaging.

Thanks to the significantly longer service life of plastic pallets and reusable containers, they do not need to be replaced as often. This positive circumstance as well as the possibility to reduce the volume of these transport packaging (folding, collapsing & nesting) means fewer transports. In addition, it can be recycled more easily and is lighter weight. All of these factors help significantly reduce emissions.

INTECH also produces green power! Our photovoltaic system delivers over 740 kWp (kilowatt peak). We use solar energy to produce reusable packaging. This is a climate-friendly approach, and our path to an ecological future.

Bioplastics are plastic materials produced from renewable biomass sources. Such products reduce the use of fossil resources and lower CO2 emissions. At INTECH, we are aware of our ecological responsibilities, and we offer our customers a variety of sustainable bioplastic solutions.

| Service life | 23-26 rotations (Medium pallet Multi-Line); approx. 3-4 years |

| CO2 footprint | 50 % smaller than Euro pallets |

| Loss rate | 60 % lower than Euro pallets |

| Recycling rate 100 % (pallet return & material tempering) | Yes |

| Produced from 100 % PCR plastic (100 % recycled material) | Yes |

| Consistent quality (maintenance and repair free) | Yes |

| Unit weight | constant |

| Mold, wetness, splinters, rusty nails | impossible |

| Service life | 10-13 rotations; approx. 1-2 years |

| CO2 footprint | 50 % bigger than plastic pallets |

| Loss rate | 60 % bigger than plastic pallets |

| Recycling rate 100 % (pallet return & material tempering) | No |

| Produced from 100 % PCR plastic (100 % recycled material) | No |

| Consistent quality (maintenance and repair free) | No |

| Unit weight | 20-24 kg (depending on moisture) |

| Mold, wetness, splinters, rusty nails | common |

Our reusable transport packaging items are durable, reusable for many years and will be 100 % recycled at the end of their life-circles.

They replace disposable packaging like cardboards or plastic films in a climate-friendly manner and improving the CO2 balance for the long-term.